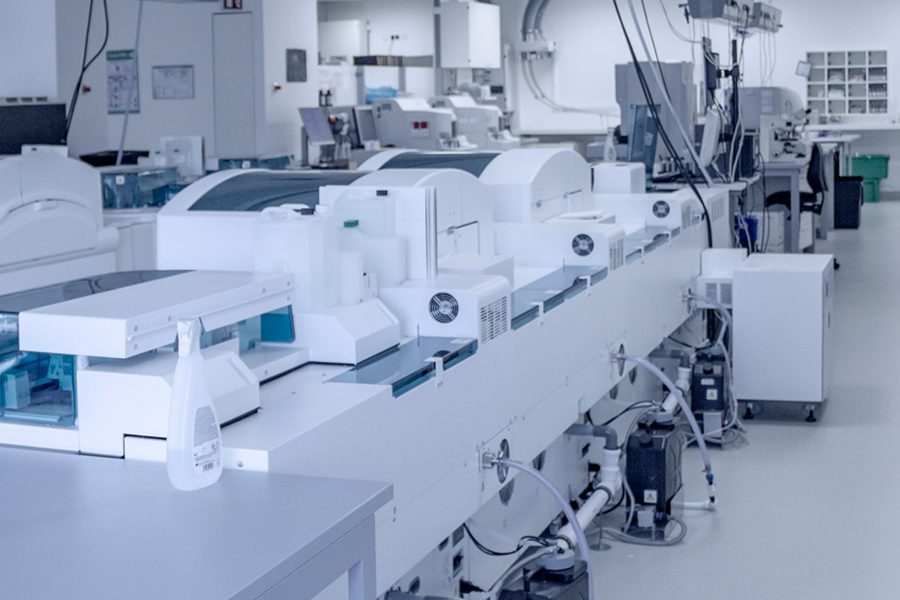

Vital Process Controls for Life Saving Industries

From the research laboratory, to medical equipment, to pharmaceutical production and packaging, vital process controls include fluid pressure measurement and regulation and fluid filtration. For these and more, Biomedical and Pharmaceutical industry OEMs depend on OKC Automation for accurate, reliable solutions.

OKC Automation’s Service is excellent. The reliability and durability of their products has allowed us to just stock their parts standardly and not have machines go down, which is important since this is a hospital.

Proven Solutions for Pressure Regulation

Suitable for the Toughest Applications

Precision fluid pressure control is of vital concern in the production of pharmaceuticals —from laboratory to packaging — in biomedical research, diagnostics and testing applications, and even in some medical equipment. To address these needs, Pressure and Vacuum Regulators, Volume Boosters, and Transducers are used extensively throughout the Medical & Pharmaceutical industries. OKC Automation offers a variety of these devices, suitable for specific uses, which meet and exceed the needs of even the toughest applications.

Research

Regulators and transducers play a vital role in research and analysis equipment. State of the art test equipment, such as that employed to develop or test protein crystallization or nanotechnology structures rely upon accurate pressure control. The highly accurate yet versatile Electro-Pneumatic Transducer is often used in this equipment because it is capable of maintaining the tight pressure control necessary.

Laboratory

In laboratory applications, such as a Glove Box, maintaining the desired mixture of gases at specific pressures is critical, as is the rapid filling or evacuation of the chamber. Pressure or Vacuum Regulators are used to maintain the chamber environment and operating pressure or vacuum. When high flow and quick response or evacuation is needed, a Volume Booster is incorporated into the system.

Fermentation

Precision control of pressure and flow of gases used during the pharmaceutical fermentation process facilitates initial growth of pharmaceutical reagents and compounds. An Oxygen Service line of Regulator and Booster products are available for use in maintaining precision introduction of Oxygen, Nitrogen or Hydrogen rich gases into the chamber to percolate and create the resultant product.

Processing

During the separation and further processing of pharmaceutical products, various Regulators and Transducers are used throughout the facility to monitor, maintain, coordinate and control pressure and flow of many different media to create the desired reactions for the products.

Purification

Transducers and Regulators are used in the pharmaceutical purification process to maintain pressures and flow of the media through the distillation and purification steps. Volume boosters are often utilized to increase the flow of gas into purification vessels.

Packaging

Vacuum packaging systems rely upon Vacuum Regulators to maintain a constant vacuum during the packaging cycle, creating durable, tamperproof seals for bags, bottles and other packaging systems.

Medical Equipment

Pressure regulation products are widely used in medical devices and diagnostic equipment. For example, in applications for doppler, photo and pneumoplethysmographs as well as other standard peripheral vascular tests, Volume Boosters are employed to increase flow through the equipment to provide quick response and enhanced ability to continuously monitor the patient.

In hospital and surgical settings, a polymer Miniature Precision Regulator is used in heart pumps and other respiratory equipment for accurate pressure control. This high-performance device is compact, lightweight, and its material is immune to most fluids and gaseous materials.

Dependable Products Fill the Critical Role of Filtration

Filtration is widely used in the Pharmaceutical Industry, with applications in many processes. Different types of filtration methods and devices are used, depending on the application. OKC Automation offers a line of miniature particulate filters, coalescing filters, regulators and filter/regulators in 316 Stainless Steel. These ensure that any compressed air system has the optimum level of filtration, a precise and consistent line pressure and, when appropriate, the correct amount of lubricant in the air. Designed to withstand caustic solutions, harsh operating conditions and demanding applications, they are ideal for the Biomedical and Pharmaceutical industries.

Questions? Call 888.487.6711

Our Technical Customer Service Representatives are ready to assist you.